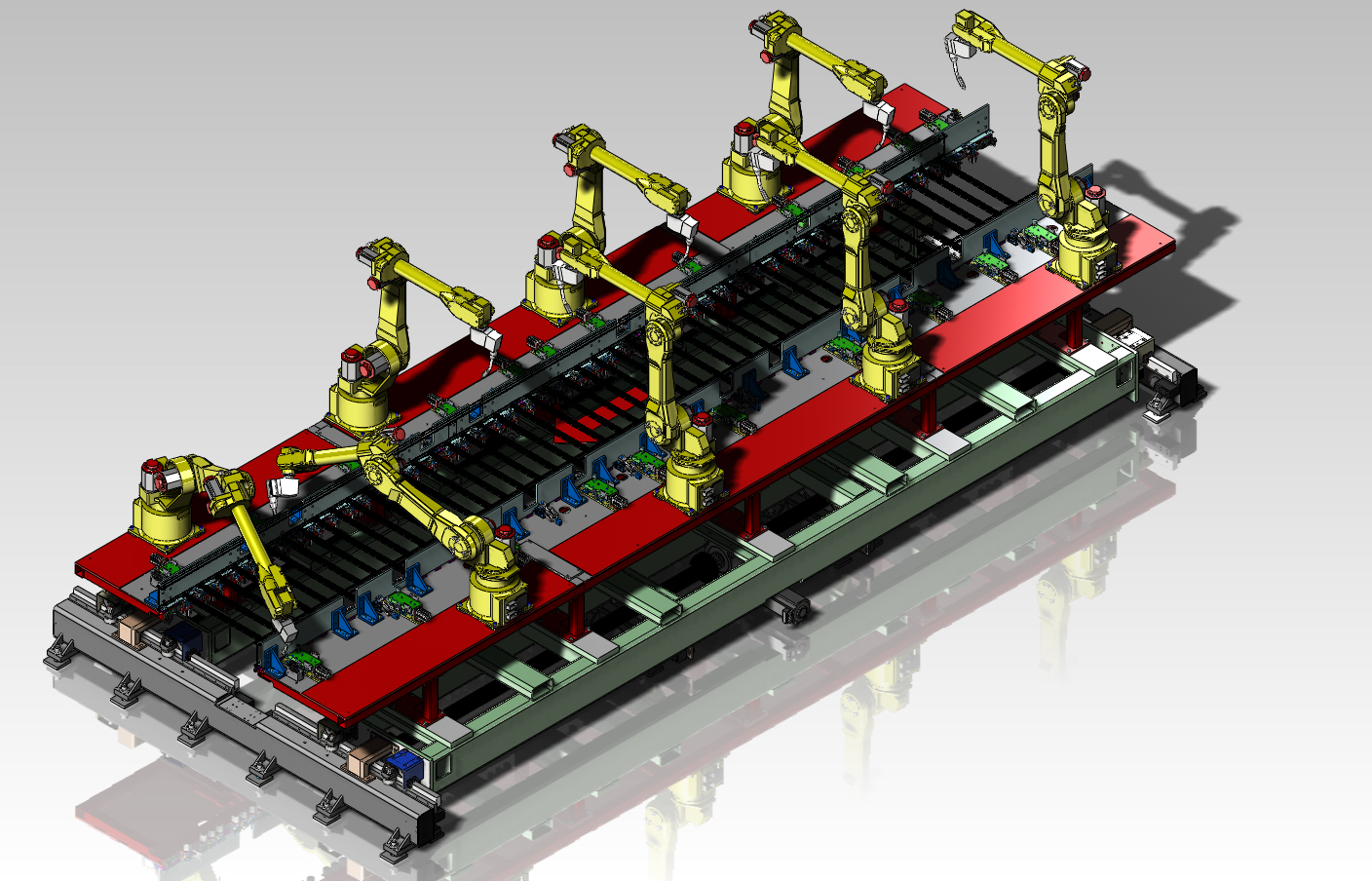

Weld Fixtures

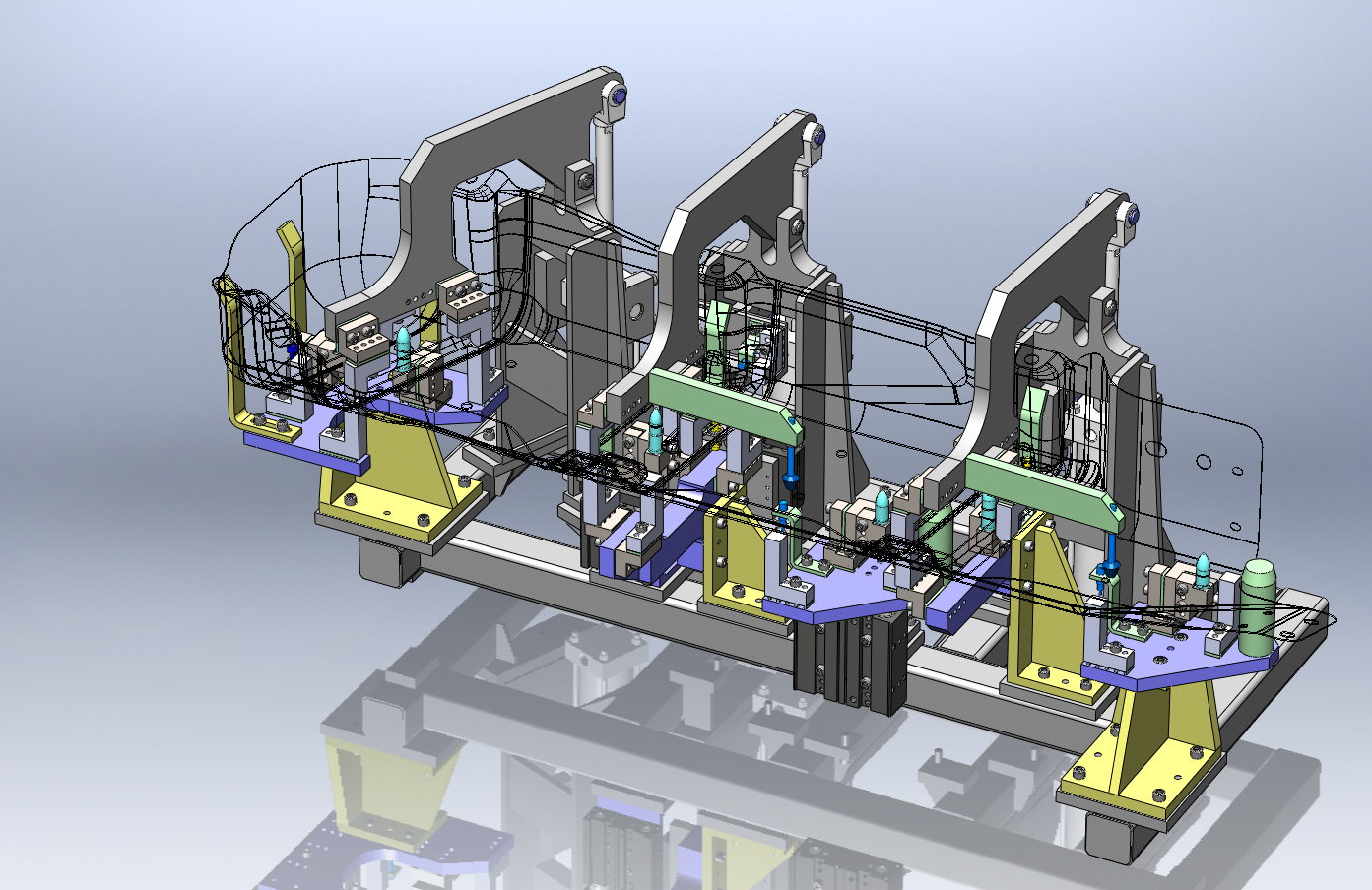

ADG has developed vast experience with weld fixtures for either robotic or manual tacking and welding operations. Solutions can feature manual or automated clamping, complex tooling, part detection, fool proofing (poka-yoke), and modular/interchangeable nesting for multiple part variations. Several layouts can also be produced ranging from flat table top styles to rotary trunnion styles.

The main criteria incorporated into each weld fixture design are:

- Relevant part datum referencing

- Ease of (un)loading

- Torch access

- Weld spatter protection

- Nest adjustability

- Robot reach studies

- Cost optimization